In semiconductor manufacturing, the wafer cover plate plays a critical role in supporting wafers during processing. The material chosen for this component has a direct impact on wafer quality and production efficiency.

Aluminum nitride (AlN) ceramics stand out as an advanced material with a unique combination of thermal conductivity, electrical insulation, and mechanical strength. With thermal conductivity reaching up to 320 W/m·K—over ten times that of alumina ceramics—AlN ensures rapid and uniform heat transfer. Its electrical resistivity exceeds 10^13 Ω·cm, and its flexural strength can reach more than 350 MPa. These exceptional properties make aluminum nitride a preferred material for wafer cover plates in semiconductor applications.

Key Advantages of Aluminum Nitride Ceramics in Wafer Cover Plate Applications

1. High thermal conductivity

Wafers undergo processing in high-temperature environments such as lithography, etching, and ion implantation. The superior thermal conductivity of AlN ceramics enables wafers to quickly reach the required process temperature, boosting production efficiency. At the same time, uniform heat distribution reduces thermal stress, minimizing defects and improving wafer yield.

2. Excellent heat dissipation

Processes like plasma etching and laser treatments generate significant heat. AlN’s strong heat dissipation capability helps transfer this heat away efficiently, preventing wafer overheating, lowering the risk of thermal damage, and maintaining processing accuracy.

3. High electrical insulation

During manufacturing, wafers are coated with conductive layers such as photoresist or anti-reflective films. The outstanding electrical insulation of AlN ceramics prevents unwanted charge accumulation between the wafer and the tray, reducing the likelihood of discharge events and safeguarding wafer integrity.

4. Robust mechanical properties

With high flexural strength and hardness, AlN ceramics resist wear and cracking during handling and transport, extending the service life of wafer cover plates. Additionally, the coefficient of thermal expansion of AlN is close to that of silicon wafers, which helps minimize thermal stress and prevents warping.

5. Corrosion resistance

Throughout semiconductor processing, the cover plate is exposed to chemicals such as etchants and photoresists. AlN ceramics offer strong resistance to chemical corrosion, ensuring long-term stability and durability in demanding environments.

6. Chemical stability and cleanliness

AlN ceramics do not react with materials on the wafer surface, preventing contamination and maintaining processing quality. Moreover, the manufacturing process of AlN ceramics is relatively eco-friendly, contributing to lower carbon emissions within the semiconductor industry.

Conclusion

As a wafer cover plate material, aluminum nitride ceramics provide high thermal conductivity, efficient heat dissipation, superior insulation, mechanical strength, corrosion resistance, and excellent chemical stability. These characteristics make them highly valuable in semiconductor production, enabling higher throughput, lower costs, and better wafer quality.

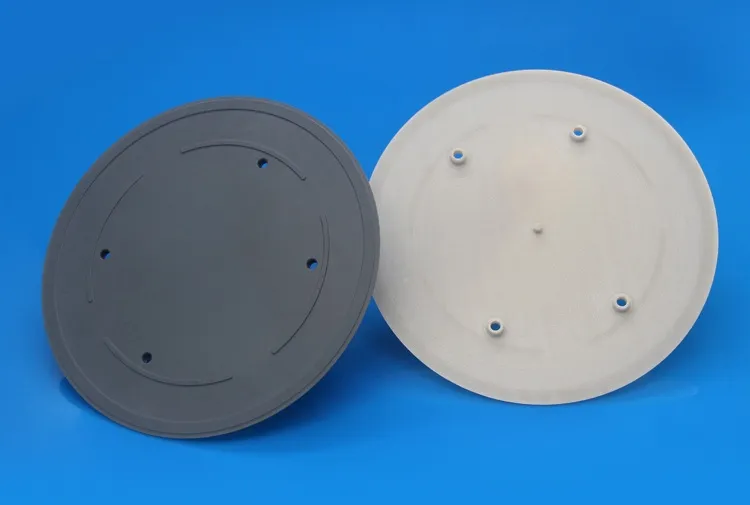

At INNOVA supplies, we offer two types of aluminum nitride ceramics: standard AlN and hot-pressed AlN. The key distinction lies in purity—hot-pressed AlN has higher purity and, consequently, better thermal conductivity.

For more details or technical inquiries, feel free to reach us at info@innovasupplies.com.