Ceramics are valued for their high melting points and outstanding insulating properties, yet these same characteristics make them notoriously difficult to join with metals. Conventional welding methods rarely deliver the strength and reliability required. To address this challenge, engineers have turned to vacuum brazing—an advanced joining technique that makes full use of the advantages of both ceramics and metals to produce robust composite components.

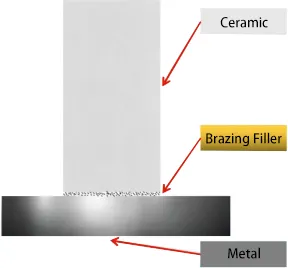

One of the key benefits of vacuum brazing lies in its high-temperature bonding process carried out in a vacuum environment. This setting minimizes oxidation and other undesirable reactions, ensuring cleaner and stronger joints. The method typically employs a brazing filler metal tailored to the ceramic and metal being joined. In the case of active metal brazing, for example, filler alloys such as Ag-Cu-Ti contain titanium, which reacts with the ceramic surface and enables the formation of a durable bond.

The inherent difficulties of joining ceramics—namely, their high melting points and limited thermal compatibility—make traditional welding inadequate. Vacuum brazing, however, offers a reliable alternative, combining the strengths of both material classes to deliver consistent, long-lasting joints. Compared with mechanical fastening or solid-state diffusion bonding, vacuum brazing stands out for its balance of performance, cost-efficiency, and practicality.

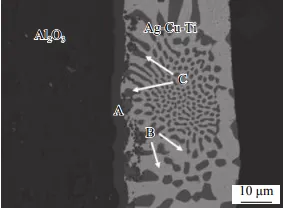

In practice, the process uses a filler alloy that melts below the base material’s temperature, allowing it to flow and bond without degrading the ceramic or metal. For ceramic-to-metal applications, active brazing with Ag-Cu-Ti powders has proven highly effective. Here, titanium in the filler actively cleans and reacts with the ceramic surface, paving the way for strong adhesion.

A common example is the brazing of Al₂O₃ ceramics to 304 stainless steel. After metallizing the ceramic surface, an AgCu filler is applied, and the vacuum brazing process produces joints capable of withstanding high-temperature testing while maintaining excellent hermeticity and reliability.

Active metal brazing has demonstrated shear strengths of up to 130 MPa, underscoring the remarkable durability achievable with this approach. Such results highlight the technology’s promise for creating ceramic-to-metal assemblies that can meet the demands of diverse high-performance applications.

As the field continues to advance, vacuum brazing is evolving with improved joint strength and broader adaptability. It has become a cornerstone technology in ceramic-to-metal joining, driving innovation in the design and manufacture of next-generation composite components.