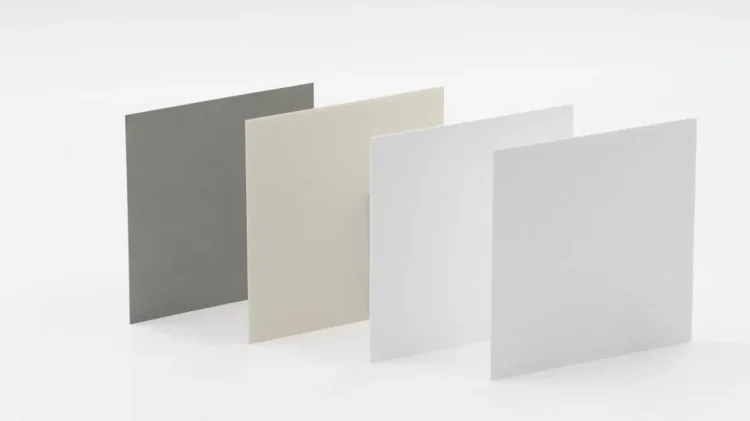

Color variation in aluminum nitride (AlN) ceramic substrates is influenced by multiple factors, including raw material quality, processing conditions, microstructural characteristics, and environmental effects. Based on related research and industrial practice, the main causes can be summarized as follows.

1. Surface Color Changes Caused by Oxidation

AlN ceramics are prone to oxidation at elevated temperatures, forming an aluminum oxide (Al₂O₃) layer on the surface. The thickness and structure of this oxide layer play a decisive role in surface color appearance.

Thermal analysis indicates that the mass change of AlN during oxidation correlates closely with the oxidation degree. As oxidation progresses at different temperature stages, gradual color shifts may occur, leading to visible chromatic differences across the ceramic surface.

2. Influence of Raw Materials and Processing Conditions

Raw material purity and synthesis route:

The preparation method has a significant impact on color consistency. For example, hydrothermal–carbothermal synthesis can enhance precursor homogeneity by controlling the formation of structures such as γ-AlOOH@C core–shell particles. However, if raw materials such as aluminum nitrate or carbon sources contain impurities (e.g., Fe or Si), these elements may remain in the ceramic and alter its color.

Protective atmosphere during sintering:

AlN ceramics are typically sintered under a nitrogen atmosphere to prevent decomposition and oxidation. Surfaces exposed to more effective nitrogen protection tend to exhibit lighter coloration, while areas with less protection may show darker tones, contributing to overall color non-uniformity.

3. Microstructure and Defect-Related Effects

Grain structure and porosity:

The coexistence of fibrous AlN polymorphs (such as 27R and 21R structures) enhances mechanical performance but can introduce anisotropy in light scattering. Variations in grain orientation and pore distribution, therefore, lead to localized color differences.

Surface morphology evolution:

During high-temperature treatment, thermal etching produces polygonal pits and step-edge features on the ceramic surface. As annealing progresses, these pits may merge into V-shaped structures, altering light reflection behavior and reducing visual color uniformity.

4. Effects of Additives and Impurities

Sintering additives:

SiO₂ are commonly added to promote densification and grain growth in AlN ceramics. While beneficial for mechanical properties, these additives may introduce subtle color changes.

Trace impurities:

Metal ions such as Fe³⁺ and Cr³⁺, introduced during raw material handling or processing, can absorb specific wavelengths through electronic transitions, resulting in noticeable chromatic deviation even at very low concentrations.

5. Testing Conditions and Observation Factors

Light source and viewing angle:

Color perception is highly dependent on illumination. Metamerism can cause the same sample to appear different under showroom lighting, natural light, or LED sources. For this reason, color evaluation should be performed under multiple light conditions.

Measurement variability:

Differences in colorimeter geometry and calibration may lead to inconsistent readings. Instrumental data should therefore be combined with visual inspection to minimize misinterpretation.

Summary and Recommendations

Color variation in AlN ceramic substrates arises from the combined effects of material composition, processing conditions, microstructure, and observation environment. To minimize chromatic inconsistency, the following measures are recommended:

- Process control: Precisely regulate sintering temperature, duration, and atmosphere to limit oxidation and impurity incorporation.

- Raw material management: Use high-purity powders and establish strict traceability and dopant control systems.

- Surface optimization: Apply polishing or surface treatment techniques to improve uniformity and reduce light scattering.

- Standardized evaluation: Combine instrumental color measurement with visual inspection under multiple light sources, and define strict acceptance criteria (e.g., ΔE ≤ 1).

These measures are essential for achieving stable color consistency in high-performance AlN ceramic substrates used in advanced electronic applications.