Semiconductor chips are at the heart of today’s digital world. From smartphones and smartwatches to computers, automobiles, cloud computing, and the Internet of Things (IoT), these chips drive the technology that shapes our daily lives. The equipment used to manufacture semiconductors consists of thousands of highly precise components, and the performance, durability, and accuracy of these parts directly affect the stability and reliability of the entire system. Among these, precision ceramic components are indispensable.

Why Precision Ceramics Matter

Ceramics are widely adopted in semiconductor equipment due to their unique material properties, including exceptional hardness, high elastic modulus, superior wear resistance, excellent electrical insulation, corrosion resistance, and low thermal expansion. These characteristics make them ideal for critical parts in tools such as wafer polishing systems, thermal processing equipment (epitaxy, oxidation, diffusion), lithography machines, deposition systems, etching tools, and ion implantation machines.

Key ceramic materials include alumina, silicon nitride, aluminum nitride, boron nitride, and silicon carbide. On average, precision ceramic components account for around 16% of the total value of semiconductor equipment.

Applications of Ceramics in Semiconductor Processes

Below is a snapshot of where ceramics play an essential role across different semiconductor processes:

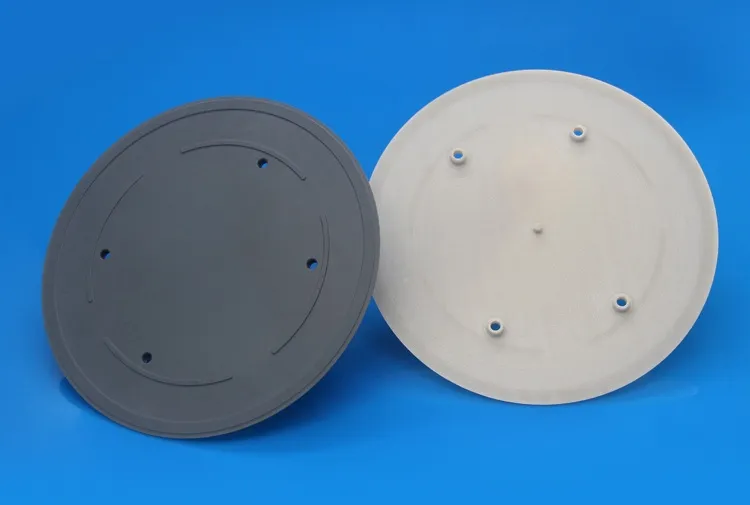

1. Chemical Mechanical Planarization (CMP)

– Polishing tables

– Polishing plates

– Lapping plates

– End effectors

– Ceramic sealing (O-rings)

2. Lithography

– Vacuum and wafer chucks

– Ceramic worktables

– End effectors

– Working wheels

– Valves

– Filters

3. High-Temperature Processing (RTP / Epitaxy / Oxidation / Diffusion)

– Insulators

– Substrates

– Wafer boats

– Furnace tubes

– Cantilever paddles

4. Deposition Equipment

– Ceramic sealing (O-rings)

– Valves

– Chamber covers and liners

– Deposition rings

– Electrostatic chucks

– Heating elements

– Electroplating insulators

– Vacuum break filters

5. Etching

– Domes

– Chambers

– Focus rings

– Nozzles

– Electrostatic chucks

– End effectors

6. Ion Implantation

– Bearings

– Vacuum chucks

– Electrostatic chucks

– Nozzles

Commitment to Excellence

At INNOVA Supplies, we combine advanced technology with a commitment to research and innovation. Every project is approached with scientific precision and careful attention to detail, ensuring we deliver solutions that meet the highest standards of quality and performance.

We invite you to share your requirements with us—we are ready to provide tailored ceramic solutions and professional support to help you achieve your goals.