In the electric drive systems of new energy vehicles—particularly motor drivers and inverters—the IGBT power module, or other power semiconductor modules, serves as the core functional unit. These modules convert battery-supplied direct current (DC) into alternating current (AC) to drive the motor while withstanding high voltages, large currents, and repeated thermal cycling. Owing to their excellent thermal stability, high mechanical strength, and outstanding electrical insulation performance, silicon nitride (Si₃N₄) ceramic substrates have become a critical foundational material for such power modules.

Within the module, silicon nitride substrates are typically used as internal support and heat-spreading layers. They directly carry IGBT or diode chips and integrate with copper conductors or metallized layers in the package, forming an “electrically insulated yet thermally conductive” core structure. This configuration ensures reliable operation of the electric drive system under conditions of high power density and harsh operating environments.

Silicon Nitride Substrate

Function and Role

(1) Heat Dissipation

During operation, power modules generate substantial heat. Silicon nitride substrates efficiently transfer this heat to the heat sink or cooling system through their relatively high thermal conductivity, thereby preventing chip overheating and improving overall module stability.

Although the thermal conductivity of silicon nitride (approximately 80–90 W/(m·K)) is not the highest among ceramic materials, its balanced combination of good heat conduction and superior mechanical strength makes it particularly well suited for electric drive systems exposed to severe temperature fluctuations and strong vibration.

(2) Electrical Insulation

Inside the power module, IGBT chips must be electrically isolated from external metal structures while still allowing efficient heat transfer. Silicon nitride substrates provide high electrical insulation alongside adequate thermal conductivity, effectively meeting the design requirement of “thermally conductive insulation.”

This function represents the fundamental value of ceramic substrates, including silicon nitride, alumina, and aluminum nitride. They form the electrical insulation framework of the power module, safely confining operating voltages that can reach several hundred or even thousands of volts within the module, while isolating them from the grounded housing and cooling system to ensure system safety.

(3) Structural Support

The internal chips, solder layers, and metallized circuits of a power module require stable mechanical support. Silicon nitride substrates offer high strength and strong resistance to thermal stress, helping to prevent warping or cracking during repeated high-temperature thermal cycles.

This capability is a key factor distinguishing silicon nitride from other ceramic materials. Its flexural strength and fracture toughness are more than twice those of aluminum nitride. During frequent acceleration and deceleration, different materials within the module—chips, solder, substrates, and copper layers—undergo continuous thermal expansion and contraction. The superior mechanical robustness of silicon nitride enables it to withstand these stresses, prevent substrate fracture or interfacial failure, and maintain long-term structural integrity.

(4) Enhanced Reliability

Electric vehicles experience frequent start-stop and braking events, subjecting power modules to extensive thermal cycling. Silicon nitride substrates exhibit excellent thermal shock resistance, which significantly extends module service life and enhances overall vehicle reliability.

Thermal shock stability represents the combined outcome of the advantages described above. Good thermal conductivity minimizes internal temperature gradients, while high mechanical strength allows the substrate to resist the resulting stresses. Industry data indicate that power modules using silicon nitride substrates can achieve temperature cycling lifetimes approximately an order of magnitude longer than those based on conventional alumina or aluminum nitride substrates. This directly impacts the durability, warranty expectations, and long-term reliability of both the electric drive system and the vehicle as a whole.

Application Forms

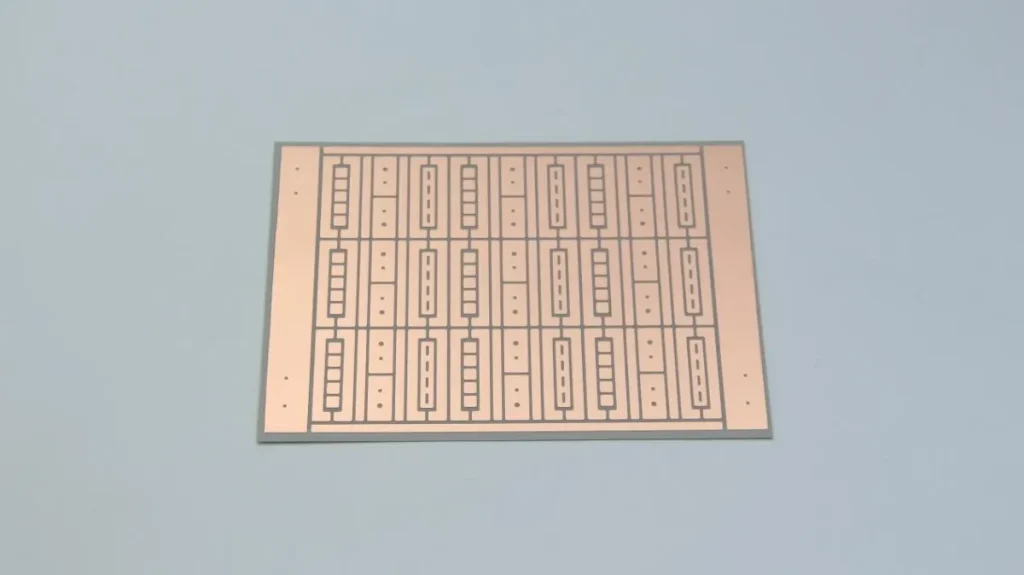

• Metallized Si₃N₄ Substrates

To enable soldering and electrical interconnection, silicon nitride substrates require surface metallization, achieved through processes such as the traditional Mo/Mn method or the widely adopted active metal brazing (AMB) technology. These metallized structures can directly support SiC or IGBT power chips and form the electrical interconnection core of the power module. Among these approaches, AMB technology has become the preferred solution for automotive-grade power modules due to its superior copper bonding strength, excellent thermal performance, and ability to meet demanding requirements for high power density, long service life, and high reliability.

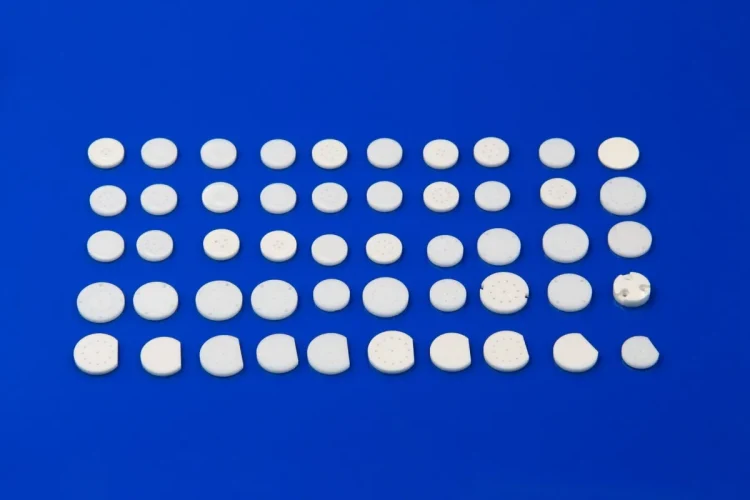

Si₃N₄ Substrate after Active Metal Brazing (AMB)

• Direct Integration in EV Power Modules

In new energy vehicle electric drive systems, silicon nitride substrates function as a “three-in-one” core carrier, simultaneously providing electrical insulation, heat dissipation, and structural support. They are directly encapsulated within the main inverter power module, securing the power chips and coupling closely with the module’s liquid cooling system through thermally conductive interface materials. This design enables efficient heat extraction from the chips and ensures stable output power and reliable long-term performance, even under intense thermal cycling caused by frequent acceleration and braking.

INNOVA Supplies offers a comprehensive range of Silicon Nitride (Si₃N₄) substrates, from standard products to fully customized solutions. For more information or technical inquiries, please contact info@innovasupplies.com.