Boron nitride (BN) is a hot-pressed hexagonal ceramic material known for its well-balanced chemical, electrical, mechanical, and thermal characteristics. Owing to this unique property combination, BN is widely used in demanding environments where conventional materials fail. In recent years, BN ceramic nozzles have attracted increasing attention in high-temperature and high-performance industries such as aerospace and semiconductor manufacturing.

The key performance advantages of BN ceramic nozzles are outlined below.

1. Exceptional Thermal Stability

BN features an extremely high melting point of approximately 2900 °C. In practical applications, BN ceramic nozzles can operate at temperatures up to 1800 °C in high-vacuum environments and 2100 °C in inert gas atmospheres, making them suitable for a wide range of ultra-high-temperature processes.

2. Excellent Thermal Shock Resistance

BN ceramic nozzles can withstand rapid and repeated temperature changes without cracking or structural failure. This outstanding thermal shock resistance allows reliable performance in processes involving sudden heating and cooling cycles.

3. Outstanding Corrosion Resistance

Boron nitride exhibits strong resistance to chemical attack from acids, alkalis, and other reactive media. This chemical inertness protects the nozzle from corrosive materials, minimizes contamination risks, and significantly extends service life.

4. Self-Lubricating Properties

BN is inherently self-lubricating, which prevents molten metals or glass from adhering to the nozzle surface. This property helps avoid clogging, ensures stable material flow, and improves overall process efficiency.

5. Superior Electrical Insulation

As an excellent electrical insulator, BN is well suited for applications involving high voltages, plasma environments, or electrically sensitive processes, where both thermal and electrical stability are required.

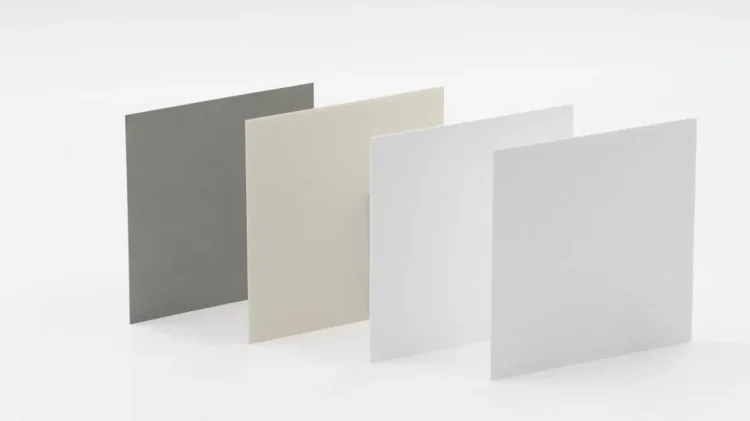

Material Property

| Material Composition | BN+ZrO2 | 99 BN |

| Density | 2.8–2.9 g/cm³ | 2.0 g/cm³ |

| Color | White Graphite | White |

| Bending Strength | 90MPa | 35MPa |

| Compressive Strength | 220MPa | 85MPa |

| Thermal Conductivity | 30 W/(m.k) | 40 W/(m.k) |

| Thermal Expansion Coefficient (20-1000°C) | 3.5 10-6/K | 1.8 10-6/K |

| Max working temperature | Inert Gas 1800 °C | Inert Gas 2100 °C |

| In High Vacuum 1800 °C | In High Vacuum 1800 °C | |

| In Atmosphere 900 °C | In Atmosphere 900 °C |

Leveraging these advantages—including high thermal stability, strong thermal shock resistance, electrical insulation, chemical inertness, and low friction—we have developed a series of BN-based nozzles for metal and glass processing, 3D printing, and advanced semiconductor and aerospace applications.

1. Metal and Glass Processing

BN ceramic nozzles are widely used in metal casting and glass manufacturing, where they are continuously exposed to molten materials at high temperatures. Their excellent non-wetting behavior toward molten metals and glass, combined with chemical inertness, ensures smooth flow, reduces clogging, and improves production consistency. For high-temperature metal and glass processing, BN nozzles represent a highly reliable solution.

2. 3D Printing

In metal additive manufacturing, BN nozzles are employed to deliver molten metals or powdered feedstock. Their thermal stability and low-friction surface promote consistent material delivery, reduce nozzle wear, and contribute to improved printing accuracy and part quality.

3. Semiconductor Industry

Within the semiconductor sector, BN nozzles are commonly used in chemical vapor deposition (CVD) and other high-temperature processes. Their ability to handle reactive gases without undergoing chemical reactions ensures precise material deposition and stable long-term operation under extreme conditions.

4. Aerospace Industry

BN nozzles are also utilized in aerospace applications such as rocket engines and thrusters. Their capability to withstand extreme temperatures and resist thermal shock makes them well-suited for directing high-velocity exhaust gases in harsh operating environments.

The wide adoption of BN ceramic nozzles in metal and glass processing, additive manufacturing, semiconductor fabrication, and aerospace systems highlights their versatility and reliability. With a combination of exceptional thermal, chemical, and electrical properties, BN nozzles continue to be a preferred choice for high-performance and high-temperature applications.