INNOVA Suppplies ceramic interface pads solve a fundamental problem: they create reliable thermal pathways between hot components (like power transistors) and their heat sinks, eliminating pesky air gaps caused by imperfect surfaces. Forget thermal bottlenecks – we fill those microscopic valleys efficiently.

Why Ceramic? Especially AlN?

We use two workhorse materials: alumina (Al₂O₃) and aluminum nitride (AlN). Here’s why they’re special:

AlN is the star performer: Its thermal conductivity blows alumina out of the water (we’re talking 7-10× better!).

Stays cool electrically: Top-tier insulation even under high voltage – no leakage, no breakdown.

Built tough: Handles crazy temperature swings (-50°C to 500°C+), laughs at corrosion, and won’t crack under stress.

Plays nice with silicon: Matches silicon’s expansion rate, so no stress cracks in your chips.

Silent partner: Zero noise, and crucially, no parasitic capacitance messing with your MOSFET/IGBT gates.

Where You’ll Use Them:

Perfect for:

Power devices (MOSFETs, IGBTs – you name it)

IC packaging thermal management

Heat sink interfacing

LED board TIM applications

COF (Chip-on-Film) cooling

Our Go-To: Aluminum Nitride Pads (No-Hole Design)

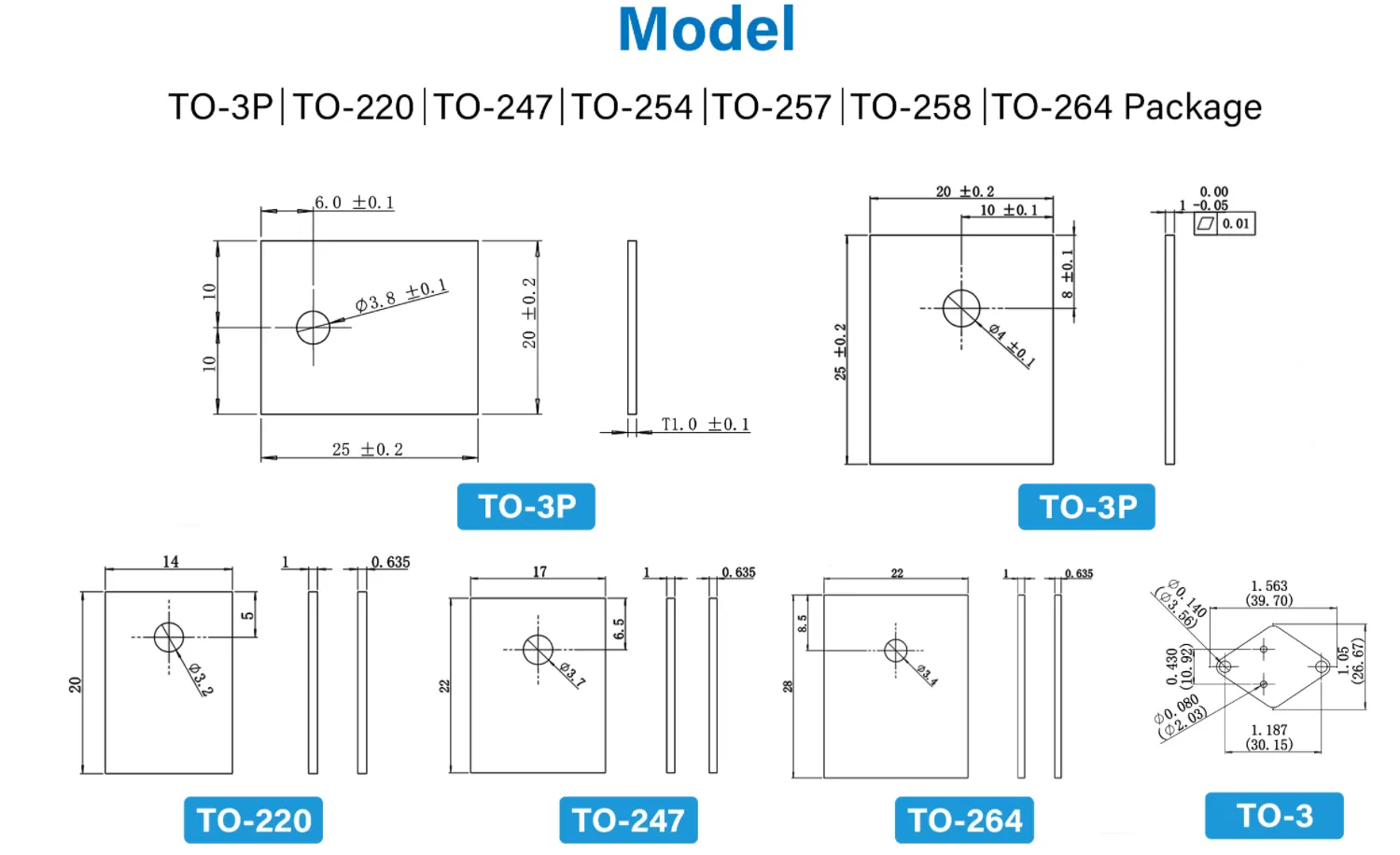

We stock AlN pads tailored for TO packages like:

TO-3P, TO-220, TO-247, TO-264, TO-3, TO-254, TO-257, TO-258

(Need holes? We do those too – just ask.)

Installation – Quick & Solid:

Prep surfaces: Clean both components thoroughly. Align the pad.

Stick the power device: Mount your transistor/MOSFET onto the pad.

Screw down: Secure the stack (device + pad + heatsink) with screws. Done.

Sizes We Keep On Hand:

Here are common dimensions (thickness typically starts at 1mm – custom thickness available):

TO Package Dimensions (L × W mm) Notes

TO-3P 25 × 20

TO-220 20 × 14

TO-247 22 × 17 Often 0.635mm thick

TO-264 28 × 22

TO-3 39.7 × 26.67 Diamond shape

TO-254 34 × 24

TO-257 40 × 28

TO-258 50.8 × 50.8 Square

Also standard sizes: 25.4×25.4, 114.3×114.3, 152×152, 190.5×138mm.

Custom cuts? Absolutely – send us your drawing.

Regular Size Drawing:

(Visual: Schematic showing pad mounting on typical TO-packaged MOSFET/IGBT)

Our Quality Standards – No Compromises:

Parameter Requirement Why It Matters

Thickness ±0.01mm (per your spec), Consistency in thermal stack

Flatness ≤ 0.01mm eliminates air pockets

Camber (Warp) ≤ 0.2% Ensures even pressure

Surface Finish Ra ≤ 0.5µm Smooth contact surface

Visuals Flawless – no chips, cracks, or stains. Reliability first

Cleaning Ultrasonic + alcohol wash, baked dry no residues, no watermarks

Handling Packed in ESD-safe pearl foam immediately prevents shipping damage

How We Pack Your AlN Pads:

Clean & dry: Every piece is ultrasonically cleaned, alcohol-rinsed, and baked dry.

Safe storage: Placed in partitioned pearl foam trays – 100pcs per cell.

Boxed smart: 5 cells per box (500pcs total), shrink-wrapped with a clear specs label.

Ship securely: Boxes go into reinforced cartons (21×21×12cm, ~1.5kg).