Thermal evaporation is a core technique in materials science and advanced manufacturing, widely used for depositing thin films with high precision and consistency. Whether in laboratory research or large-scale industrial production, the performance of the evaporation components directly affects coating quality and process stability. Designed to meet these demanding requirements, boron nitride (BN) ceramic evaporation boat sets have become essential tools, valued for their reliability, efficiency, and versatility.

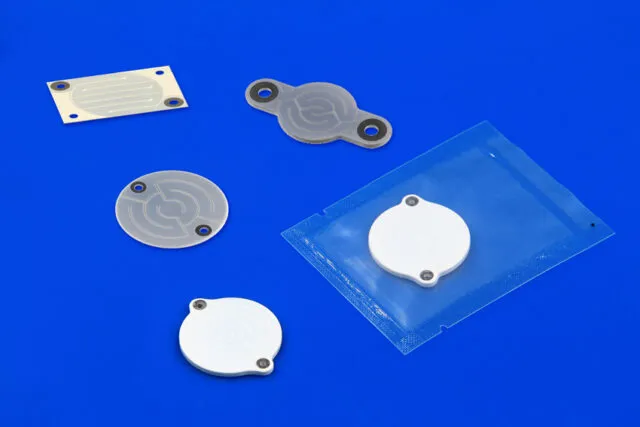

INNOVA Supplies offers a comprehensive range of boron nitride ceramic evaporation boat sets that are readily available for immediate use. With cumulative sales exceeding 10,000 units, this product line has proven its reliability and strong market acceptance. These BN ceramic evaporation boats function similarly to internally heated ceramic containers and are suitable for a wide variety of metal evaporation processes. They are commonly used for precious metals such as gold and silver, as well as base metals and alloys, including copper, zinc, nickel, and chromium.

One of the key advantages of boron nitride evaporation boats is their ability to achieve complete and efficient metal evaporation with minimal material loss. Additionally, they can be reused in conjunction with tungsten baskets, thereby improving the overall process economy. Developed through advanced ceramic engineering, these evaporation boats offer a practical and high-performance solution for both research laboratories and industrial thermal evaporation applications. Available capacities range from 0.25 ml to 3 ml, allowing users to select the most suitable size for their specific process requirements.

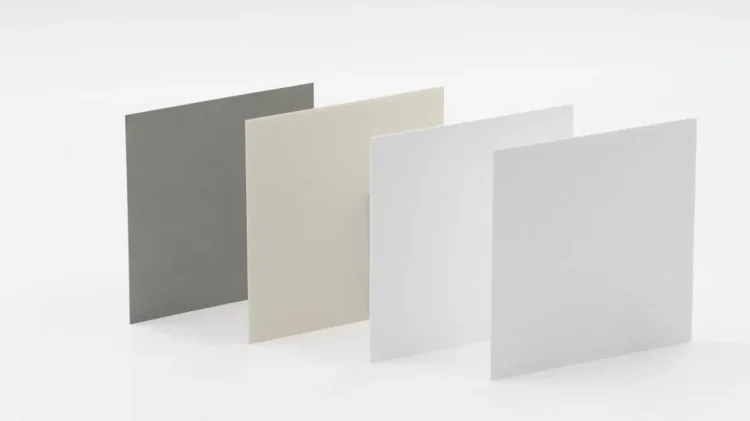

INNOVA Supplies specializes in the research, development, and manufacturing of boron nitride ceramic products. Its portfolio includes insulating components, crucibles, tubes, rings, sheets, precision-shaped parts, evaporation boats, nozzles, and other BN ceramic products. These materials are widely applied in high-end industries, including ultra-high-temperature equipment manufacturing, powder metallurgy and gas atomization, thermal plastic forming, optical glass production, horizontal continuous casting, amorphous ribbon manufacturing, technical ceramic sintering, phosphor sintering, metal casting, electronics, superhard materials processing, semiconductor fabrication, and aerospace technology.

The outstanding performance of boron nitride ceramic evaporation boats is attributed to several key material characteristics:

- High purity: Ensures minimal contamination during evaporation, resulting in high-quality thin films.

- Low gas content: Reduces outgassing during heating, preventing interference with deposition processes.

- High density: Provides excellent mechanical strength and resistance to thermal shock during repeated heating cycles.

- Uniform grain structure: Guarantees consistent thermal, mechanical, and chemical properties throughout the material.

- Good compactness: A dense microstructure enhances durability and process stability.

- Complete evaporation capability: The optimized design enables most metals to evaporate fully and efficiently, maximizing material utilization.

Together, these advantages make boron nitride ceramic evaporation boats a reliable and high-performance choice for modern thermal evaporation applications across research and industrial environments.