What Is a PBN Heater?

PBN refers to pyrolytic boron nitride, a high-purity ceramic material produced by chemical vapor deposition (CVD) at elevated temperatures. In contrast, conventional BN typically refers to hot-pressed cubic boron nitride. Due to differences in manufacturing processes, PBN components are generally produced with a thickness of 3 mm or less.

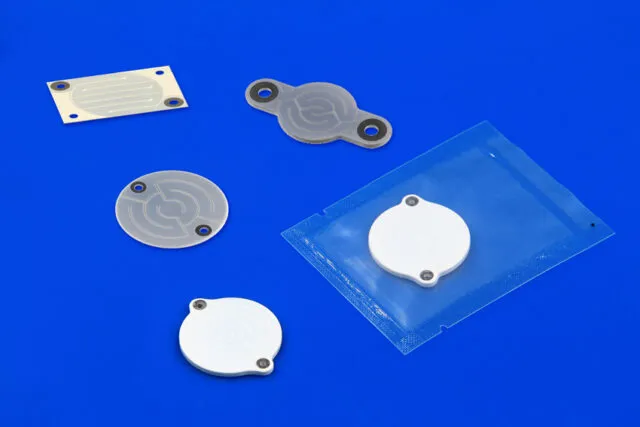

A PBN heater is a graphite-based heating element fabricated on a PBN substrate. A thin graphite layer is deposited onto the PBN surface and then patterned—commonly by laser engraving—into a graphite heating circuit. Afterward, the graphite heating layer is encapsulated with an additional PBN coating, leaving only the electrode areas exposed. This structure forms a fully integrated graphite heater insulated by PBN.

Manufacturing Methods

There are generally two processing approaches:

Method 1 (Recommended):

Grooves are first machined into a PBN sheet, followed by deposition of pyrolytic graphite into the circuit pattern. A final PBN coating is then deposited over the graphite layer to encapsulate the heating circuit. The overall thickness is typically around 3 mm. Voltage and current are customized to customer requirements, usually favoring low voltage and high current for rapid heating. This method provides reliable insulation and long-term stability.

Method 2 (Not Recommended):

In this approach, graphite is machined into grooves and then coated with PBN on both sides. However, when graphite is used directly as the heating element under alternating current, magnetic resonance effects may occur. These effects can cause the PBN coating to delaminate over time, making this method unreliable for long-term use. As a result, this process is generally not recommended.

In summary, the standard PBN heater design uses PBN as both the substrate and the insulating encapsulation layer, while heat generation is provided by the graphite heating track.

Why Is This Structure Used?

Graphite and pyrolytic graphite are widely used in heating applications due to their excellent electrical and thermal properties. However, under high-temperature and vacuum conditions, graphite can continuously release impurities, posing a contamination risk to ultra-pure processes and materials.

By encapsulating the graphite heating element within a dense, non-porous PBN layer—with its low thermal expansion coefficient and excellent chemical inertness—these impurities are effectively blocked. This design protects sensitive materials from contamination while maintaining stable heater performance. Even after repeated thermal cycling, the PBN coating remains firmly bonded and resistant to peeling.

Advantages and Operating Considerations

PBN heating elements offer excellent chemical stability and corrosion resistance. Typical operating temperatures reach up to approximately 1200 °C, and the heaters can function in oxygen atmospheres as low as 10⁻⁵ mbar.

During operation, rapid and extreme temperature changes should be avoided to prevent separation between the PBN encapsulation and the graphite layer. Proper electrical contact at the electrodes is also critical, as poor contact can lead to localized overheating and potential electrode damage.

Key Performance Characteristics

- Maximum temperature in vacuum: 1650 °C

- Maximum temperature in air: 300 °C (not recommended)

- Suitable for high vacuum, ultra-high pressure, and corrosive environments

- Extremely fast heating rates with very low thermal mass

- Chemically inert and highly stable

- Pyrolytic graphite elements fully encapsulated in PBN and unaffected by deposition by-products

- Samples can be placed directly on the heated ceramic surface

- Available in sizes up to 4 inches, square or round

For custom designs or larger heater sizes, please contact our technical sales team for further assistance.