Aluminum Nitride (AlN) wafer substrates have become an essential material in today’s semiconductor industry, valued for their outstanding thermal and electrical performance. Their compatibility with silicon makes them particularly attractive for a wide range of wafer-level applications, where both reliability and efficiency are critical.

Why Aluminum Nitride Wafer Substrates Matter

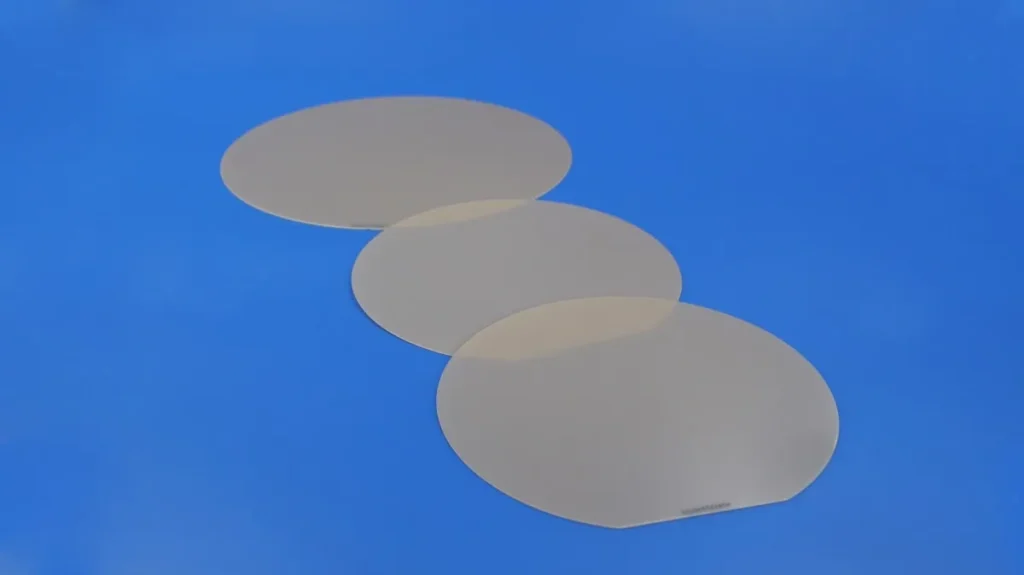

AlN substrates play a fundamental role in enabling stable semiconductor device operation. One of their most important advantages is their thermal expansion behavior, which closely matches that of silicon. This alignment reduces thermal stress at the wafer interface, making AlN an excellent choice wherever heat management is a concern. INNOVA Suppplies , a recognized supplier in this field, provides AlN substrates in diameters from 2 inches to 8 inches, with 6-inch and 8-inch formats most commonly adopted in high-volume manufacturing.

Distinctive Properties of Aluminum Nitride

The properties of AlN make it particularly well suited for next-generation electronics. Some of its key attributes include:

- High Thermal Conductivity: With values ranging from 170–220 W/mK, AlN efficiently dissipates heat in demanding semiconductor devices.

- Electrical Insulation: Its high resistivity provides excellent electrical isolation, essential for power and high-frequency circuits.

- Low Dielectric Constant: AlN’s low dielectric constant minimizes signal loss and distortion, helping preserve the integrity of high-frequency signals.

- Mechanical Robustness: The material’s strength and dimensional stability protect devices against deformation, extending operational life.

- Corrosion Resistance: Strong resistance to molten metals and corrosive environments enhances durability in challenging applications.

- Chemical and Thermal Stability: AlN maintains its performance under extreme temperatures and harsh conditions, preventing long-term degradation.

Aluminum-Nitride-Wafer-Substrates

Applications Across the Semiconductor Industry

The combination of these properties makes AlN substrates highly versatile across different semiconductor sectors:

- Power Electronics: Efficient heat conduction and electrical isolation are crucial for managing the high loads of modern power devices.

- RF and Microwave Components: Low dielectric constant and strong thermal performance make AlN a preferred material for high-frequency circuits.

- LED Production: By effectively dissipating heat, AlN substrates improve LED efficiency and service life.

- Wafer Bonding: INNOVA Suppplies ’s polished AlN wafers (Ra ≤ 0.05 µm) meet the demanding surface requirements for direct wafer bonding, where flawless flatness and smoothness are essential.

Looking Ahead

Aluminum Nitride wafer substrates provide a balance of thermal conductivity, electrical insulation, and mechanical integrity that few other materials can match. INNOVA Suppplies’s product range, offered in multiple sizes and customizable formats, supports the evolving requirements of advanced semiconductor manufacturing.

As the industry continues to push toward higher power densities, faster signal speeds, and more compact designs, the role of AlN substrates will only grow. Selecting AlN not only enhances device performance but also extends reliability, making it a solid investment for high-performance electronics and emerging technologies.