Aluminum nitride ceramics, composed primarily of aluminum nitride, are known for their outstanding thermal conductivity, excellent electrical insulation, and low dielectric constant. Their crystal structure features tetrahedral units bonded covalently, forming a spinel-like configuration within a hexagonal system. Chemically, aluminum nitride consists of 65.81% aluminum and 34.19% nitrogen, with a density of 3.261 g/cm³. The material typically appears white or grayish-white, while single crystals remain transparent and colorless. With a sublimation decomposition temperature reaching 2450 °C at standard pressure, aluminum nitride is well-suited for high-temperature environments. Its thermal expansion coefficient falls between 4.0 and 6.0 × 10⁻⁶/°C, and its polycrystalline form can achieve thermal conductivity values of up to 260 W/(m·K)—five to eight times higher than alumina—providing excellent thermal shock resistance up to 2200 °C. Aluminum nitride is also highly resistant to molten aluminum and other metals, offering exceptional corrosion resistance in demanding operating conditions.

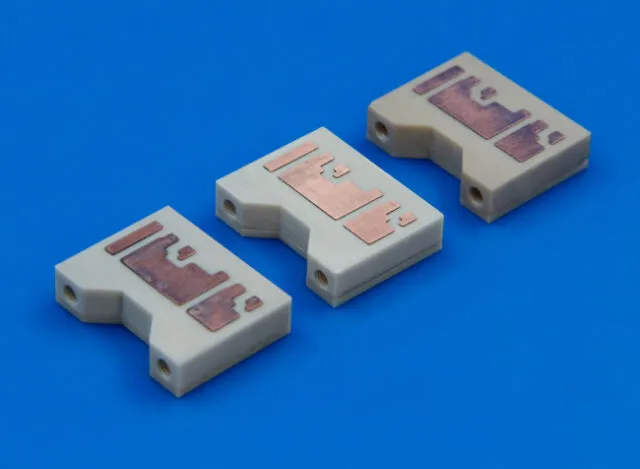

Although several machining techniques are available for aluminum nitride ceramics, achieving high precision typically requires CNC machining. The difficulty stems largely from the material’s significant hardness—exceeding 11 GPa—which renders conventional metalworking methods impractical.

To begin with, machining aluminum nitride demands specialized tools and approaches distinct from those used in metal processing. Tool materials such as tungsten steel are unsuitable, as they wear rapidly when cutting hard ceramics. Polycrystalline diamond (PCD) tools are generally preferred because their diamond structure allows them to efficiently grind and machine aluminum nitride components.

Establishing an appropriate machining path is equally important. During CNC processing, issues such as edge chipping—particularly after piercing operations—commonly occur. Well-designed tool paths help prevent these defects and significantly improve the final quality of aluminum nitride ceramic parts.

Machine selection is another critical factor. Due to the hardness of aluminum nitride, vibration levels during machining are noticeably higher than with metals or softer materials. Standard CNC machines often lack the rigidity required to manage these forces, resulting in tool chatter or compromised spindle precision. For best results, dedicated ceramic machining centers—designed with reinforced rigidity—are recommended. These machines reduce vibration, protect spindle components, and provide better overall durability against abrasive ceramic debris.

It is worth noting that these challenges are not unique to aluminum nitride; many advanced ceramics exhibit similar machining difficulties due to their extreme hardness and brittleness. Successfully processing such materials requires both high-level machining expertise and specialized equipment.

In summary, machining aluminum nitride ceramics is demanding because of their exceptional hardness and distinctive material characteristics. Overcoming these challenges calls for precision tooling, thoughtful machining strategies, and purpose-built equipment.