As the new energy vehicle industry continues to advance, thermal management of batteries—one of their core components—has become an issue of growing significance. Effective temperature regulation in both high and low temperature conditions is crucial to ensuring battery performance, durability, and safety.

1. The Role of Ceramic Materials in Battery Thermal Management

Ceramic materials offer several distinct advantages in battery thermal management, making them a preferred choice in many high-performance applications. One of their most notable properties is high thermal conductivity. During operation, batteries generate substantial heat, and ceramics facilitate efficient heat transfer away from critical areas, helping to maintain optimal operating temperatures. This not only enhances performance and service life but also mitigates safety risks related to thermal runaway.

Additionally, ceramics exhibit exceptional resistance to high temperatures. They retain structural and chemical stability even under extreme thermal conditions, avoiding degradation that can compromise functionality. This reliability makes them particularly suitable for demanding battery applications where thermal fluctuations are common.

Another key advantage is their corrosion resistance. Battery systems are often exposed to humid or chemically aggressive environments. Ceramics demonstrate long-term durability under such conditions, reducing the need for maintenance and lowering overall energy consumption. This contributes to prolonged battery life and enhanced system integrity.

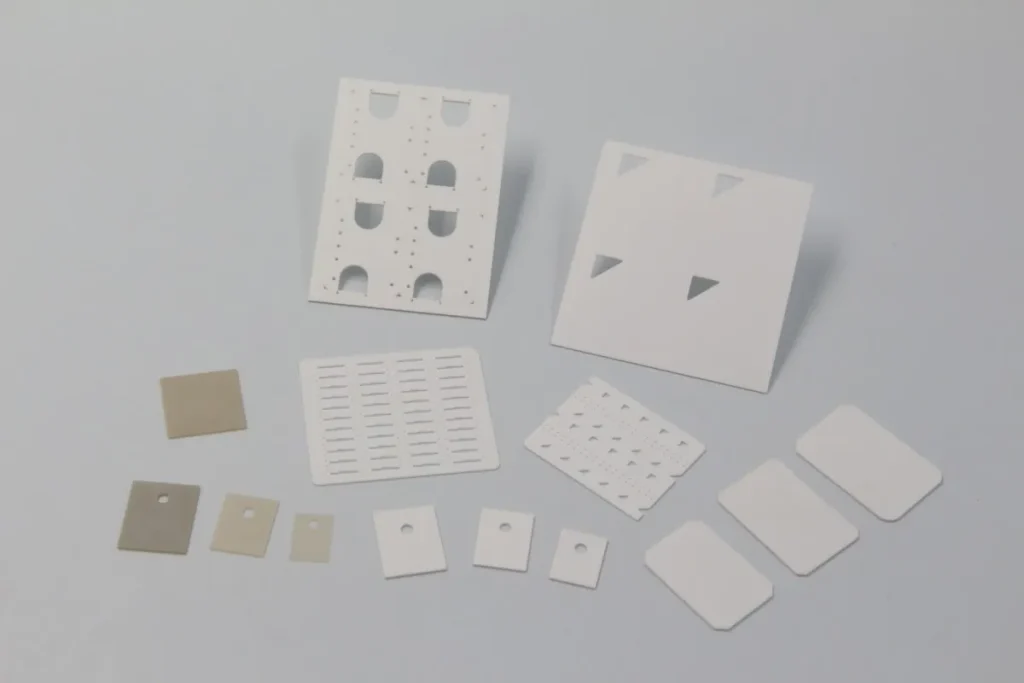

ceramic-material

2. Application Scenarios for Ceramic Materials in Thermal Management

Ceramics are used in several key areas within battery thermal management systems, leveraging their thermal and mechanical properties.

2.1 Battery Enclosure Thermal Insulation

The choice of material for battery enclosures significantly affects internal temperature stability. Compared to metals, ceramics possess lower thermal conductivity, which helps isolate the battery from external temperature variations. This thermal insulation maintains a consistent internal environment, preventing performance fluctuations caused by ambient conditions. Furthermore, ceramics provide electrical insulation, adding a layer of safety against current leakage or short circuits.

2.2 Thermal Interface Materials Within the Battery

Integrating ceramic-based materials inside battery modules improves heat conduction from the core to the cooling systems. Their high thermal conductivity allows rapid dissipation of heat, reducing the rate of temperature rise during operation. This results in more stable performance and a lower risk of heat-related failure.

2.3 Heat Dissipation Packaging

Ceramics are also employed in thermal packaging solutions thanks to their favorable thermal conduction properties. Their high thermal conductivity minimizes thermal resistance, enabling more efficient heat transfer from battery components to cooling interfaces. Moreover, ceramics offer mechanical strength and dimensional stability, ensuring that thermal pathways remain effective and reliable over time.

Ceramic-substrate

2.4 Battery Cooling Plate Design

In cooling plate applications, ceramics help distribute heat evenly across battery cells, minimizing temperature gradients. Their thermal stability and conductivity allow efficient mitigation of hot spots, which is essential for maintaining uniformity in cell temperature and enhancing overall cycle life.

In summary, ceramic materials play an essential role in multiple aspects of battery thermal management—including insulation, thermal conduction, dissipation, and thermal balancing—due to their superior thermal properties, resistance to high temperatures, and corrosion stability.

For further inquiries, please feel free to contact us.