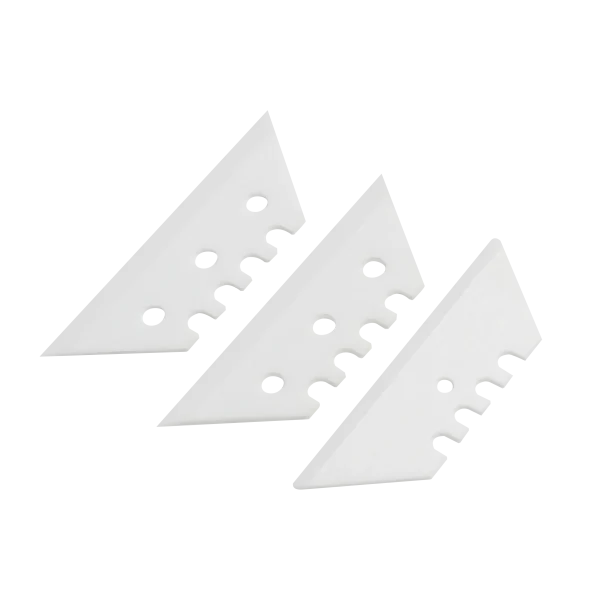

Zirconia Ceramic Trapezoid Utility Blades – 10 Pack Replacement Blades

Product Properties

Downloads & Resources

| Resource Type | Link |

|---|---|

| Safety Data Sheet (SDS) | ZrO2-MSDS-Innovacera |

| Technical Data Sheet (TDS) | Zirconia Ceramic Material Properties – SU0451 |

Product Details

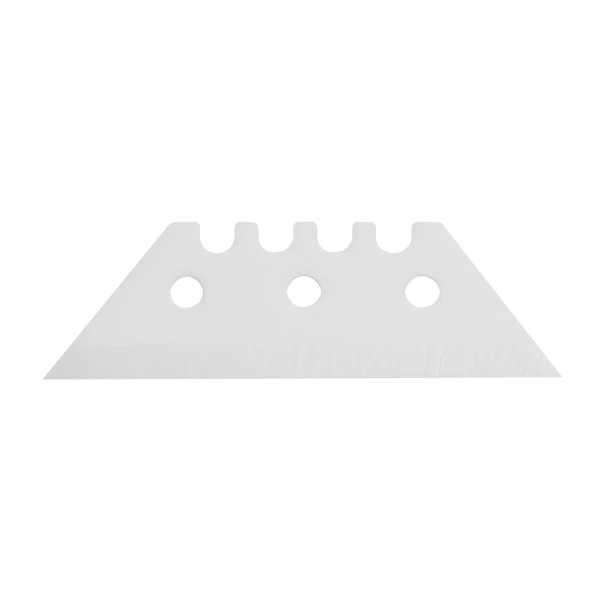

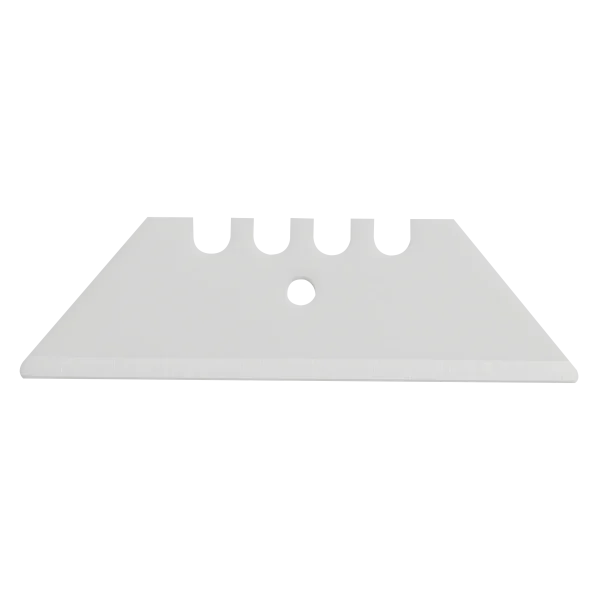

High-Performance Trapezoid Zirconia Ceramic Blades

Crafted from premium zirconia ceramic, these trapezoid-shaped blades deliver precise, clean cuts for a variety of materials. The trapezoid design ensures stability and accuracy during cutting tasks.

Durable & Wear-Resistant

Made from high-hardness zirconia ceramic, these blades resist wear and maintain their sharp edge over repeated use, reducing the need for frequent replacements.

Versatile Use for Many Materials

Ideal for cutting paper, cardboard, foam board, plastic sheets, fabric, rubber, and vinyl. Perfect for crafts, packaging, DIY projects, and general utility knife tasks.

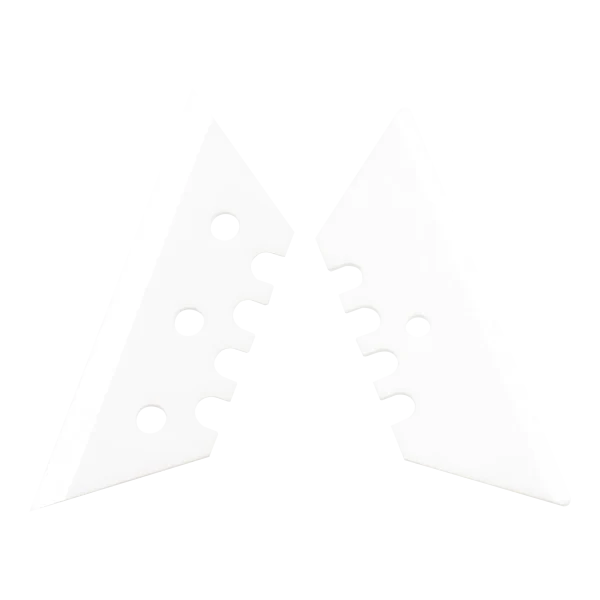

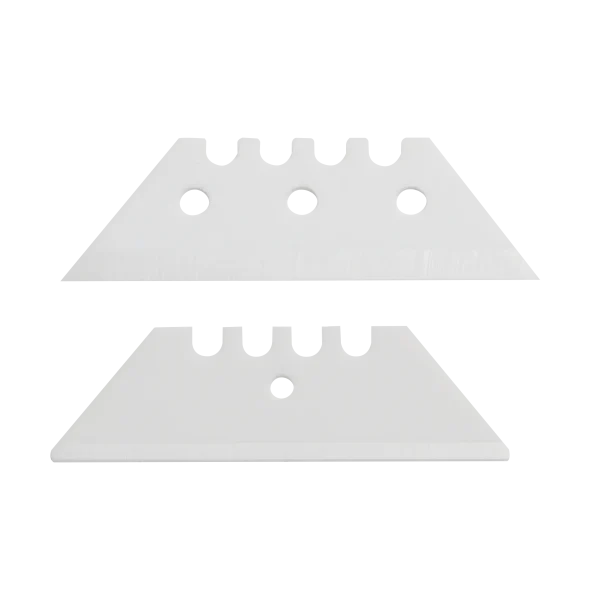

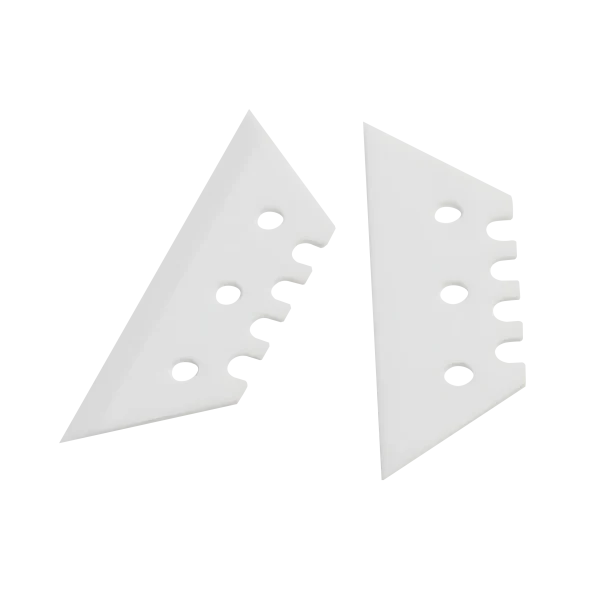

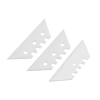

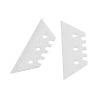

Two Tip Styles — Rounded-Tip or Pointed-Tip

Choose the rounded-tip style for safer general cutting, or the pointed-tip style for precise, detailed work.

Corrosion-Resistant & Low Maintenance

Unlike metal blades, the ceramic composition resists rust and corrosion, and is suitable for humid or chemically aggressive environments.

Lightweight & Easy to Handle

The low-density ceramic reduces hand fatigue during extended use, ideal for repetitive cuts or detailed craft projects.

Great Value — 10 Pack for Continuous Use

Selling as a bundle of 10 trapezoid ceramic blades ensures a long-lasting supply for workshops, craft rooms, or everyday utility knife use.

Frequently Asked Questions

Zirconium oxide (chemical formula: ZrO₂) is an inorganic compound composed of zirconium and oxygen elements. It is the most stable oxide form of zirconium in the Earth’s crust. It is one of the most abundant metal oxides in Earth’s crust and is also an important raw material for high-performance ceramics, refractory materials, and functional materials in modern industry. Pure crystalline zirconium oxide rarely exists alone in nature. It is usually distributed in the form of secondary minerals within minerals such as zirconite (ZrSiO₄), and can be obtained with high purity through chemical purification or high-temperature treatment of zirconite.

The core characteristics of zirconia ceramics can be summarized as: extremely high strength and toughness (bending strength 900-1200 MPa, fracture toughness 5-10 MPa·m¹/², excellent impact resistance), durability in harsh environments (melting point 2715℃, resistant to high temperatures, resistant to strong acids/corrosion/maintenance), excellent biocompatibility (foundation for medical implant safety) , aesthetic performance similar to natural teeth (adjustable light transmission), and through doping, functional expansions such as piezoelectric/ion conduction are achieved, making it an ideal material for cross-domain high-end applications.

1. Powder: High-purity zirconium oxide powder, doped zirconium oxide powder, active zirconium oxide powder

2. Grinding media: Zirconium oxide balls/pebbles, zirconium oxide rods/rollers

3. Structural ceramic parts: Dental restorations, industrial wear-resistant parts (bearings, sealing rings, valve sleeves, cutting tool coatings)

4. Refractory materials: Zirconium oxide bricks/modules, zirconium oxide casting materials, zirconium oxide fibers

5. Fillers: Spherical zirconium oxide fillers, nano zirconium oxide fillers

6. Catalyst carriers: Porous zirconium oxide carriers, nano zirconium oxide catalysts

7. Special products: Transparent zirconium oxide ceramics, zirconium oxide films/coatings, 3D printed zirconium components

8. Biomedical products: Zirconium dental implants, zirconium-based bone repair materials

There are significant differences between the two in terms of composition, crystal structure, and properties: Zirconia ceramics consist of a single zirconia component, with larger grains, and are mostly monoclinic at room temperature. They tend to undergo phase transformation at high temperatures. Although they have excellent hardness, wear resistance, and chemical stability, their toughness is poor. In contrast, zirconia toughened ceramics are engineered through the introduction of proprietary stabilizing phases, forming a highly stable crystal structure or dual-phase microstructure, which results in a more stable cubic phase or two-phase structure. This significantly enhances their toughness and fracture toughness.

The color of zirconia ceramics is closely related to their properties. Different additives (such as rare earth elements, metal elements, oxides, etc.) can cause zirconia ceramics to exhibit different colors and properties. Common colors of zirconia ceramics include white, black, pink, blue, etc. For example, blue zirconia ceramics are prepared by adding a small amount of copper, iron, nickel, etc. as metal elements to the traditional zirconia ceramics. The color of pink zirconia ceramics is related to the type and content of the added rare earth elements.

Zirconia material is widely applied. In dentistry, it is used in full-ceramic crowns, implants, etc., balancing strength and aesthetics; in industry, it is used as refractory materials and wear-resistant components; in the electronics field, it can be used to make piezoelectric components, oxygen sensors, etc.; in biomedical fields, it is used as artificial bones and joint implants; it is also applied in new energy and environmental protection fields, such as solid-state battery electrolytes, catalyst carriers, etc.

The density of zirconia is approximately 1.5 times that of alumina. Its structure is denser and the surface is smoother. Its toughness is 2-3 times that of alumina. It has better impact resistance, thermal shock resistance, fatigue corrosion resistance and oxygen ion conductivity at high temperatures. However, its cost and processing difficulty are higher. On the other hand, alumina has better high-temperature stability and chemical stability at high temperatures. It is an excellent insulator and has a lower cost.

1. Purity and impurity control: ZrO₂ content ≥ 94.5% + type of stabilizer; critical impurity limits

2. Structural density: volume density, apparent porosity, grain size 1-3 μm (preventing low-temperature phase transformation)

3. Mechanical properties: Vickers hardness, flexural strength, fracture toughness, BMA wear rate

4. Compatibility with working conditions: high-temperature parts must be tested for thermal expansion coefficient, electronic parts must strictly control the volume resistivity

Mainly affected by raw materials (such as fluctuations in zirconium ore supply, environmental policies and production restrictions, etc.), market supply and demand (changes in demand in traditional and emerging fields, factors such as industry monopolies and capacity control affecting supply), product characteristics and quality differences (material purity, processing techniques and precision), brand positioning (premium pricing of well-known brands, market segmentation strategies), regions and channels (economic level differences, cost of sales levels), and exchange rates and international trade (import costs, policy changes), these factors jointly act, influencing production costs, market circulation and product added value, ultimately resulting in price differences.

Suggested measures:

1. Dry environment: Store in a clean, dry, well-ventilated warehouse to prevent moisture; the relative humidity should generally not exceed 60%, avoiding the risk of condensation, and use a dehumidifier to control the humidity; strengthen the inspection for water leakage during rainy seasons.

2. Temperature control: Different from alumina, the recommended storage temperature for zirconium oxide is 15-30℃ to avoid extreme temperature fluctuations.

3. Avoid contamination: Keep away from chemicals, oil stains, etc.; store separately, isolate high-purity products; zirconium oxide is sensitive to metal ions (such as Fe, Cr), and should avoid direct contact with metal containers.

4. Handle with care: For ceramic items and other products, handle with care to avoid high-hardness materials colliding and generating debris.

5. Powder sealing: Zirconium oxide powder has slightly stronger hygroscopicity than alumina, so it needs to be frequently checked for sealing; take measures to prevent leakage.

6. Other: Avoid long-term exposure to light, strengthen anti-static measures, make product labels, avoid coexistence with acidic substances, etc.

My History

No products in history.