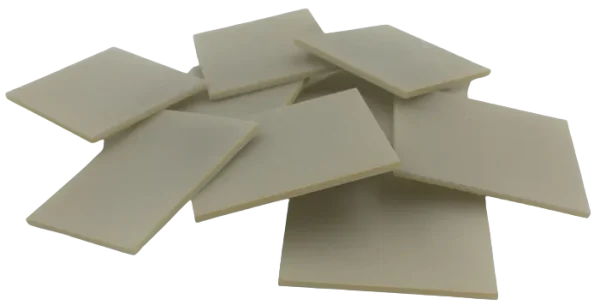

TO-220 Aluminum Nitride Ceramic Thermal Pads For MOSFET Transistor IGBT Transistor Heat Sink

| Formula | AlN | |

|---|---|---|

| Forms | ||

| Materials | ||

| Purity | 95% | |

| CAS Number | 24304-00-5 | |

| Commodity | Ceramic Thermal Pads | |

Product Properties

Downloads & Resources

| Resource Type | Link |

|---|---|

| Safety Data Sheet (SDS) | MSDS-AlN |

| Catalogue | Aluminum_Nitride_Ceramic_Thermal_Pads |

| CAD/Drawings | TO-220-K3.2-T0.6-24 TO-220-K3.2-T1-24 TO-220-K3.8-T0.6-24 TO-220-K3.8-T1-24 TO-220-T0.6-24 TO-220-T1-24 |

Product Details

INNOVASUPPLIES Ceramic Thermally Conductive Interface Pads are designed to provide a preferential heat-transfer path between heat-generating components, heat sinks, and other cooling devices. The pads are used to fill air gaps caused by imperfectly flat or smooth surfaces, which should be in thermal contact. The pads are made of ceramic materials such as alumina ceramic and aluminum nitride, which help in providing enhanced thermal conductivity and excellent insulation performance. Typical applications include Power Devices, Integrated Circuit (IC) chip packaging heat conduction, MOSFET Transistor, IGBT Transistor Heat Sink, MOS Transistor, heat sink interface, LED board Thermal Interface Material (TIM), Chip ON Film (COF) heat conduction.

Regular Size:

For Package Type: TO-220, With Hole or Without Hole.

TO-220, 20*14*1mm (other thickness is available, too);

Ceramic Thermal Pads Installation Steps:

①Clean the target surface: Clean the dust or stains on the surface of the object to be installed, and then align the hole position of the ceramic insulating sheet.

②Power tube bonding: Stick the power tube on the ceramic insulating sheet.

③Fixed the insulation sheet: Use screws to fix the power tube and ceramic insulating sheet on the installation object.

Product Package requirement:

(1) The product is cleaned according to the requirements, after being completely dried, placed in the special pearl cotton packaging box,

(2) One group of 100 products is placed in the small cells in the packaging box. There are 5 cells in each packaging box, and 500 pieces can be placed in total.

(3) After each version of the packaging box is filled with products, it needs to wrap the film tightly, and attach the quantity label.

(4) Put the pearl-cotton packing box into the outer carton, paste the specification and quantity label on the surface.

(5) Package carton size: 21*21*12cm

(6) Gross weight: 1.5 kg

Frequently Asked Questions

Aluminum nitride (chemical formula: AlN) is an inorganic compound composed of aluminum and nitrogen. It is a stable ceramic phase formed when aluminum reacts with nitrogen gas under high-temperature conditions. It is an important high-performance ceramic material, electronic packaging material, and heat dissipation material in modern industry. Pure aluminum nitride does extremely difficult to naturally exist in nature and usually needs to be synthesized artificially (such as the direct nitridation method, carbon thermal reduction method, or chemical vapor deposition method) to produce high-purity powder, which is then sintered and formed into functional components.

1. High thermal conductivity: The thermal conductivity is 8-10 times that of aluminum oxide, suitable for efficient heat dissipation scenarios (such as power modules, LED substrates, etc.)

2. Excellent electrical insulation: Resistivity > 10¹⁴ Ω·cm, resistant to high voltage (breakdown field strength > 15 kV/mm), can be used for electronic packaging and insulating components.

3. Chemical stability: Resistant to molten aluminum and copper corrosion, resistant to radiation, without toxic by-products, the product lifespan is three times that of aluminum oxide in metal melting crucibles and high-purity material evaporation vessels.

4. Low thermal expansion coefficient (4.5×10⁻⁶/℃): Close to silicon (Si), reduces thermal stress, avoids semiconductor packaging thermal stress cracking, and reliability far exceeds that of aluminum oxide.

5. Functional scalability: Through doping (such as yttrium stabilization), the crystal form can be regulated to achieve specific properties (such as enhancing mechanical strength or thermal shock resistance).

Aluminum nitride products come in various forms. Common forms include:

1. Powder: High-purity aluminum nitride powder, doped aluminum nitride powder, nano-sized aluminum nitride powder.

2. Grinding and dispersion media: Aluminum nitride grinding balls/microbeads, aluminum nitride grinding rods.

Electronic packaging substrates: DBC substrate, AMB substrate, LTCC substrate.

3. Structural ceramic components: Heat sinks/heatspools, industrial wear-resistant parts (bearings, sealing rings, valve linings, etc.)

4. High-temperature devices: Aluminum melting crucibles/semiconductor trays.

5. Functional fillers: Spherical/nano-sized aluminum nitride fillers, aluminum nitride whiskers.

6. Specialized products: Aluminum nitride films/coatings, 3D printed aluminum nitride components.

1. Aluminum nitride ceramics: Have significant advantages but are limited by cost and processing.

Advantages include high thermal conductivity (5-8 times that of aluminum oxide), good thermal matching, excellent high-frequency performance, and resistance to extreme environments; disadvantages are high cost (3-5 times that of aluminum oxide) and high brittleness, making processing difficult.

2. Aluminum oxide ceramics: Have good cost-effectiveness, but have limited thermal conductivity.

Advantages include low cost, balanced mechanical properties, resistance to chemical corrosion, and good biocompatibility; disadvantages are poor thermal conductivity, weak thermal matching, and high high-frequency loss.

The core differences between the two can be summarized as: Aluminum nitride wins with its performance, but has high costs and processing barriers; Aluminum oxide takes the lead with cost-effectiveness and mature processing technology, but has a performance ceiling.

1. High-power electronic packaging: high-power LEDs, IGBT (insulated gate bipolar transistor), laser diodes, RF power amplifiers, etc.

2. Semiconductor manufacturing equipment: electrostatic clamps (ESC) in wafer processing, heaters, carriers, etc.

3. New energy and environmental protection fields: solid-state battery electrolytes, bipolar plates for hydrogen fuel cells.

4. High-temperature structural components: coating for turbine blades in aircraft engines, inner linings for rocket combustion chambers, thermal protection systems for hypersonic aircraft.

5. Precision processing tools: super-hard tool coatings, abrasives, mold materials.

Aluminum nitride is irreplaceable in scenarios that require high thermal conductivity, high insulation, high temperature resistance, resistance to thermal shock, and chemical stability. It is particularly suitable for:

1. Thermal protection for the miniaturization and high-powerization trend of electronic devices (such as 5G base stations, electric vehicle inverters);

2. The extreme pursuit of safety and energy density in new energy technologies (such as solid-state batteries, hydrogen fuel cells);

3. The structural and functional integration requirements in extreme environments (high temperature, high pressure, strong corrosion) (such as aircraft engines, rocket combustion chambers).

1. Chemical purity of AlN content (≥99.5%), content of impurity elements (such as O, Si, Fe, C, etc.)

2. Physical properties: particle size and distribution, specific surface area (SSA), morphology (spherical or nearly spherical powder/plate-like or needle-like powder)

3. Thermal properties: thermal conductivity, thermal expansion coefficient (CTE), heat resistance

4. Electrical properties: volume resistivity, dielectric constant (εr), dielectric loss (tanδ)

5. Mechanical properties: bending strength, hardness, fracture toughness (KIC)

6. Processing characteristics: sintering shrinkage rate, processability, surface roughness (Ra)

7. Oxygen content (core indicator): <0.8 wt% (each increase of 0.1% → thermal conductivity ↓ 30W)

8. Others: copper layer peeling force (for electronic substrates), hydrolysis sensitivity (storage critical), etc.

1. Japan (Technology Dominator): With enterprises like TDK Chemical and Kyocera having long held a dominant position in the high-end market, controlling the supply chain of high-end powders and substrates. They lead in high-purity technology in aluminum nitride powder production.

2. China (Mid-to-Low End Capacity Expander): Relying on complete industrial chains in places like Jiangsu and Guangdong, there is an adequate supply of mid-to-low-end products with an annual increase of 30%, but the high-end relies on imports.

3. Europe and America (Specialized Domain Leaders): The United States focuses on Germany leads in automotive-grade substrates. The entire European and American camp does not pursue production scale but achieves irreplaceable performance in specific scenarios.

4. Others: The combined reserves of aluminum nitride powder in Canada and Russia account for the majority of global reserves, but mining is restricted by environmental policies.

1. Moisture prevention is crucial: The environmental humidity must be strictly controlled at <10% RH. Do not use water-based cleaners to clean the storage area; during transportation and handling, dry inert gases (such as nitrogen) should be filled into the packaging to prevent air from entering; storage containers should be selected with excellent sealing properties, such as metal drums or plastic drums, and desiccants (such as silica gel) can be added to the inner layer.

2. Isolate oxygen and high temperature: Aluminum nitride will react with dry oxygen above 800℃, generating aluminum oxide (Al₂O₃), causing the material to become brittle.

3. Store in different forms: Powder form uses double-layer sealed packaging, and is evacuated or filled with nitrogen gas. When storing, place it at a higher position to avoid direct contact with ground moisture. During packaging, operations should be carried out in a dry glove box.

Ceramic pieces or block-shaped products are prone to absorbing moisture. Long-term exposure may lead to the expansion of micro-cracks. They should be stored dry and dehumidified. Use moisture-proof paper or plastic film for thin isolation and stacking. Regular inspections and timely handling are required.

Generally, aluminum nitride that gets damp and turns white is difficult to restore its original properties through conventional methods. The decision on whether to scrap or downgrade its use depends on the degree of dampness. The reason is that aluminum nitride will undergo hydrolysis with water in a humid environment, generating aluminum hydroxide and ammonia gas, resulting in a white powder-like substance (aluminum hydroxide) on the surface of the material. At the same time, the internal structure may become loose and porous due to the gases produced during the reaction. This process is irreversible and significantly reduces the material’s thermal conductivity, mechanical strength, and insulation properties.

My History

No products in history.