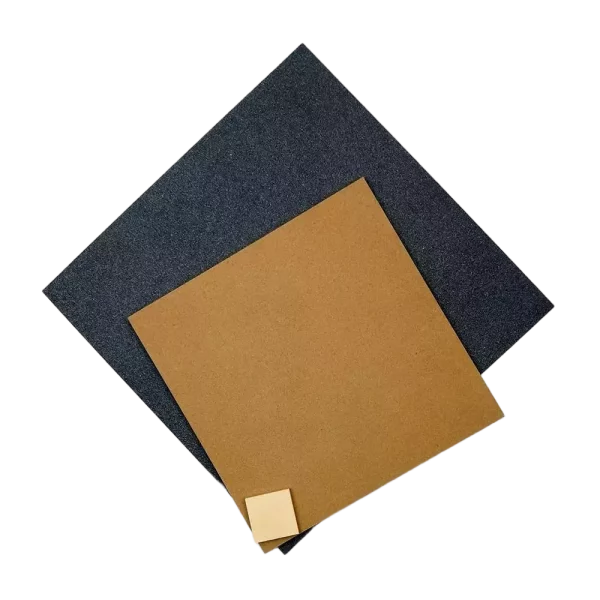

203.2mm (8 inch) Square Al2O3 Micro-Porous Ceramic Plate

| Formula | Al₂O₃ | |

|---|---|---|

| Forms | ||

| Materials | ||

| Purity | 80% | |

| CAS Number | 1344-28-1 | |

| Commodity | Ceramics Plate | |

Product Properties

Downloads & Resources

| Resource Type | Link |

|---|---|

| Safety Data Sheet (SDS) | 96% Alumina MSDS-Innovacera |

| Catalogue | Porous_Ceramics |

Product Details

Innova supplies uses its deep ceramics expertise and process capabilities to manufacture ceramics with precisely controlled porosity. Porous ceramics are often used for chemical filtration and fluid separation.

The range of Innovacera porous ceramics is made from aluminum oxide and silicon carbide. The strong, uniform porous ceramic has 40-50% open porosity with a tortuous pore structure and is available in pore sizes ranging from 1 to 100 microns.

Three Main Applications of Porous Ceramic:

- Vacuum Chuck, like scribing machine vacuum chuck, silicon wafer vacuum chuck.

- Adsorption platform.

- Suspension platform.

Especially, they are widely used in the semiconductor industry, like LED wafer processing.

The micro-porous ceramic working disk is a special tool for adsorption and bearing in various semiconductor wafer production processes, and is applied to processes such as thinning, dicing, cleaning, and handling.

They can be used with Japan, Germany, Israel, the United States, and domestic equipment, like Disco, ADT, K & S, Applied Materials TSK, OKAMOTO, Micro Automation, Load Point.

The detailed regular size is as below:

| Regular size | 6*6, 8*8, 12*12 inches | |

| Regular Tolerance (Length, Width) | +/-0.10 mm | |

| Regular Flatness | +/-0.10 mm | |

| Regular Surface Roughness | Ra 0.8-1.6 | |

| Alumina (Al2O3) | Pore Size | Color |

| 15μm | Light Brown | |

| 30μm | Brown | |

| 50μm | Blue-Gray | |

| 100μm | Blue-Gray | |

Frequently Asked Questions

Alumina (chemical formula: Al₂O₃) is an inorganic compound composed of aluminum and oxygen elements. It is the most stable form of aluminum in Earth’s crust. It is one of the most abundant oxide mineral raw materials in the earth’s crust (second only to silicon dioxide), and it is also an important ceramic base material and chemical raw material in modern industry.

There are various crystal forms of alumina, including γ, δ, θ, α, etc. Additionally, there are less common forms such as η, κ, and χ. These different crystal forms of alumina exhibit significant differences in structure, properties, and formation conditions. Among them, α-Al₂O₃ (corundum) is the most stable, has the highest density, and also has the highest hardness and strength among all crystal forms.

It has high hardness (9 on the Mohs scale, with top-notch wear resistance), a high melting point (2050°C, resistant to high temperatures), excellent mechanical strength and low thermal expansion coefficient (resistant to thermal shock); and also possesses high-temperature electrical insulation properties (high resistance/low dielectric loss) and chemical corrosion resistance (resistant to acids, alkalis, organic solvents, except hydrofluoric acid and strong alkalis); specific grades have biocompatibility (essential for medical implants), and its comprehensive performance ensures its irreplaceable role in industries, electronics, and healthcare.

1. Powder: Raw material powders of different purity and particle size (used in ceramics, refractory materials, etc.); Active alumina powder (used as a desiccant, adsorbent, catalyst and catalyst carrier, etc.).

2. Grinding media: Alumina pebbles (used in ball mills for grinding), alumina microbeads (suitable for ultrafine grinding fields).

3. Structural ceramic parts: Such as liners, refractory bricks, crucibles, nozzles, wear-resistant components, substrates, seals, ceramic tools, textile ceramic parts, etc.

4. Refractory materials: Aggregate, fine powder, casting materials, bricks (high alumina bricks, corundum bricks), etc.

5. Fillers: Used for reinforcing composite materials, spherical alumina fillers.

6. Catalyst carriers: Porous alumina balls or columns, nano-alumina catalyst carriers.

7. Special products: Such as fused corundum, transparent ceramics, alumina fibers, etc.

Purity refers to the percentage of alumina (Al₂O₃) in the material by mass.

There are differences in various aspects such as chemical purity, grain size, specific surface area, sintering performance and physical properties between different purity levels of

Alumina products are widely applied in ten core fields: metallurgical industry (aluminum electrolysis, steel-making auxiliary materials), refractory materials (kiln linings, casting materials), ceramic industry (structural components such as grinding media/tools, functional components such as electronic substrates), electronic semiconductor (substrates/sealing/pixels), mechanical equipment (wear-resistant seals/nozzles), chemical and petrochemical industry (catalysts/anti-corrosion linings), medical and health industry (artificial joints/dental implants), environmental protection and energy conservation (adsorbents/battery coatings), building materials and decoration (aggregates/coating fillers), and grinding and polishing (grinding media/polishing powder). Their fundamental nature, durability and multi-functionality have supported their comprehensive penetration from heavy industry to cutting-edge technology.

Composition and structure: purity (Al₂O₃%), key impurities (limit values of Na₂O/SiO₂), grain size (<2μm for high strength) and porosity;

Mechanical properties: Vickers hardness, flexural/compressive strength, BMA wear rate (core of grinding media);

Surface accuracy: tolerance grade, roundness/roughness (Ra value);

Compatibility with working conditions: For high-temperature parts, thermal expansion coefficient and thermal conductivity must be tested; for electronic parts, dielectric strength must be strictly controlled.

The price differences are mainly driven by the differences in comprehensive costs and technical value-added: the control level of raw material purity (such as the content of key impurities), the sintering process route (affecting energy consumption and performance), the microstructure requirements (density/grain size), the strictness of quality control (batch stability cost), the order scale effect (diluting fixed costs), the complexity of processing (the yield of irregular parts), and the brand service premium. This results in a several-fold difference in the actual performance (strength, dielectric properties, etc.) and cost of the same nominal purity products.

Although alumina is chemically stable and non-toxic in itself, the following safety matters should be noted when using it:

1. Dust: Work in a well-ventilated area and wear a dust mask to prevent inhalation of dust; dust accumulation poses an explosion risk, so regularly sweep and dust-proof.

2. Fragments/Sharp Edges: Use protective tools for handling to avoid impact and cracking of ceramic pieces; broken pieces are sharp waste and should be handled in accordance with regulations.

3. High Temperature: High-temperature components can cause burns, so use heat-resistant tools and wear heat insulation protective clothing; wait for full cooling before handling and do not cool quickly to avoid damage to the components.

4. Others: Pay attention to the operating status of related electrical equipment and conduct regular inspections and maintenance; understand the chemical properties of alumina to avoid exposing the product to incompatible chemical environments; staff must strictly follow all relevant safety operation procedures.

Suggestions:

① Dry environment: Store in a clean, dry, and well-ventilated warehouse to avoid moisture (especially for powder and un-fired raw materials); the relative humidity should generally not exceed 60%, avoid the risk of condensation, and use a dehumidifier to control the humidity; strengthen the inspection for water leakage during rainy seasons.

② Avoid contamination: Keep away from chemicals, oil stains, etc.; store different types of alumina separately, and place high-purity products separately.

③ Handle carefully: Choose appropriate handling tools, handle ceramic pieces and other products gently to avoid collision and shock;

④ Seal the powder: Alumina powder should be stored in a sealed manner to prevent moisture absorption and leakage.

Other: Avoid long-term exposure to light, control temperature, conduct regular inspections, make product labels, and take measures for fire prevention and static electricity protection, etc.

My History

No products in history.